Products

Custom size installable silicone products

1 Uses: It can be widely used in aviation, electronics, petroleum, chemical, machinery, electrical appliances, medical, oven, food and other industrial sectors with good electrical insulation and liquid transportation materials. Precision representatives, oil pipelines, household appliances sealing, drinking water pipeline sealing, medicine, etc. Silicone tube and all kinds of rubber steel wire tube, EPDM rubber tube, cloth wire tube, EPDM wire hose, foam tube, high temperature resistant hose, silicone tube, silicone cloth and automobile pressure resistant flame retardant tubing. 2 Material: Silicone tube is also a kind of rubber tube, oil-resistant and heat-resistant. Rubber tube has many applications due to different types of rubber. Commonly used rubber tube materials include EPDM,CR,VMQ,FKM,IIR,ACM,AEM, etc. Common structures include single-layer, double-layer, multi-layer, reinforced, non-reinforced, etc. 3: packaging: according to the specific product packaging.

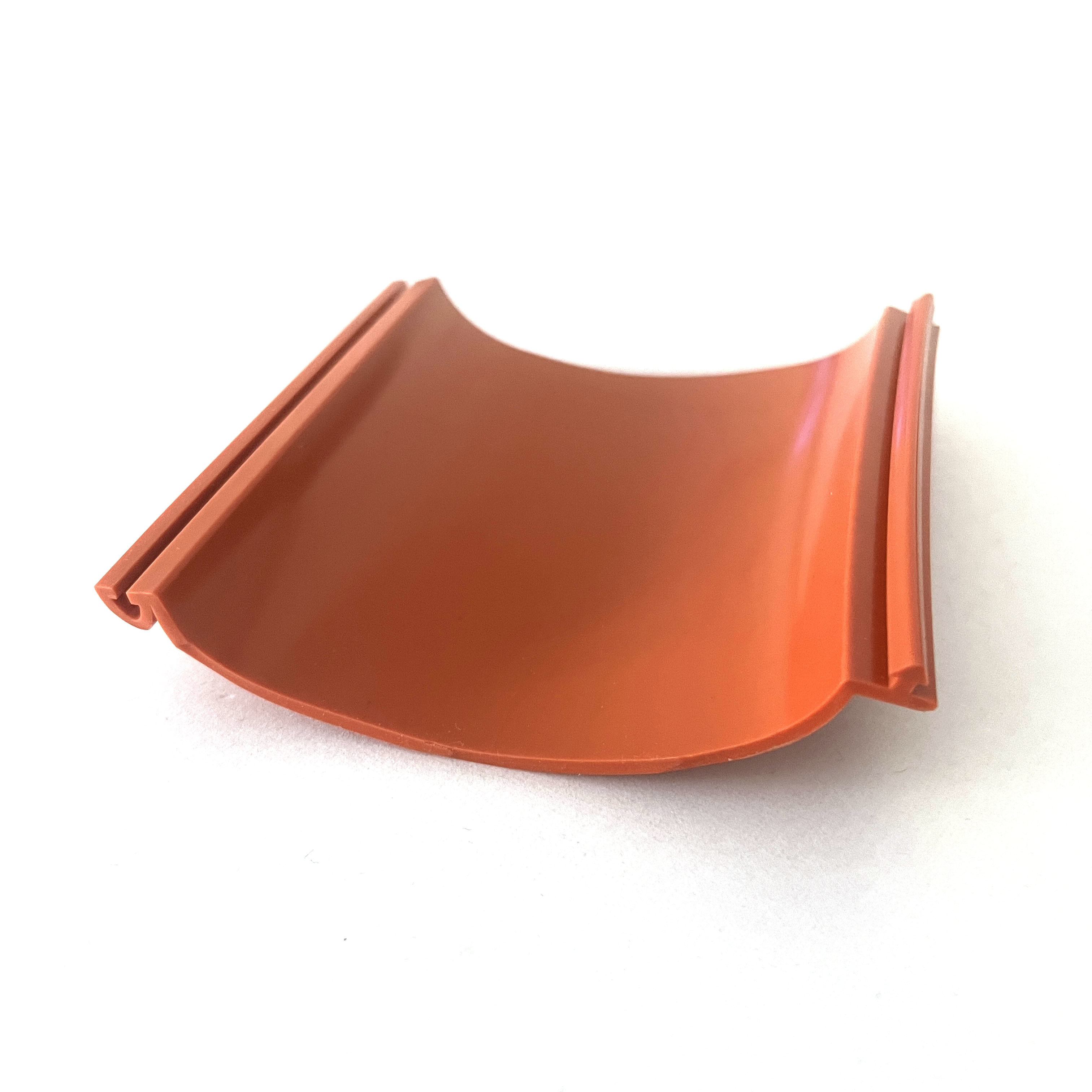

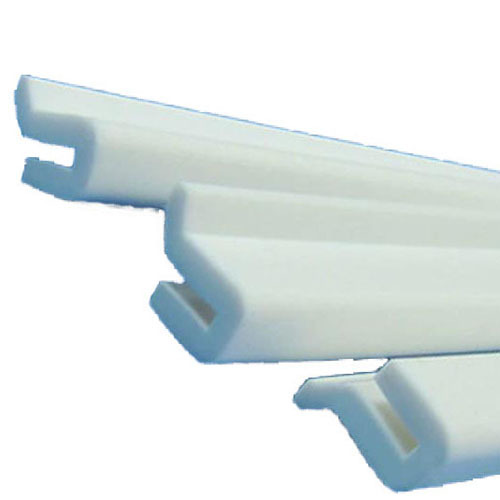

Use: ● Silicone material has good sealing performance, high temperature resistance, weather resistance, aging resistance, shockproof and waterproof, and can fit all kinds of smooth surface materials ● Can back the tape self-adhesive, better sealing, high temperature resistant adhesive long-term use does not fall off. Environmental protection and safety, good insulation, high temperature resistance, small compression deformation, strong resilience, non-toxic ● Foamed silicone rubber foam evenly, density can be 0.25-0.85g/cm3, Shore hardness 8-30A. Environmentally friendly, non-toxic and odorless, good resilience, good flexibility, no bubbles on the surface, no pores. High strength, long service life, product insulation environmental protection, high and low temperature resistance, compression resistance, acid and alkali resistance, anti-aging, anti-ultraviolet. ● 100% high-quality silicone raw materials, and after strict testing, in line with environmental standards. ● Heat resistance: Silicone rubber has much better heat resistance than ordinary rubber, and can be used almost forever at 150 degrees without performance change; it can be used continuously for 10 hours at 200 degrees; it can also be used for a period of time at 350 degrees. Weather resistance: ordinary rubber is rapidly degraded under the action of ozone generated by corona discharge, while silicone rubber is not affected by ozone. And for a long time under ultraviolet and other climatic conditions, its physical properties only change slightly. ● Silicone sealing strip color variety, according to specifications, color and packaging can be arbitrarily according to customer requirements for processing and production

Use: ● Silicone material has good sealing performance, high temperature resistance, weather resistance, aging resistance, shockproof and waterproof, and can fit all kinds of smooth surface materials ● Can back the tape self-adhesive, better sealing, high temperature resistant adhesive long-term use does not fall off. Environmental protection and safety, good insulation, high temperature resistance, small compression deformation, strong resilience, non-toxic ● Foamed silicone rubber foam evenly, density can be 0.25-0.85g/cm3, Shore hardness 8-30A. Environmentally friendly, non-toxic and odorless, good resilience, good flexibility, no bubbles on the surface, no pores. High strength, long service life, product insulation environmental protection, high and low temperature resistance, compression resistance, acid and alkali resistance, anti-aging, anti-ultraviolet. ● 100% high-quality silicone raw materials, and after strict testing, in line with environmental standards. ● Heat resistance: Silicone rubber has much better heat resistance than ordinary rubber, and can be used almost forever at 150 degrees without performance change; it can be used continuously for 10 hours at 200 degrees; it can also be used for a period of time at 350 degrees. Weather resistance: ordinary rubber is rapidly degraded under the action of ozone generated by corona discharge, while silicone rubber is not affected by ozone. And for a long time under ultraviolet and other climatic conditions, its physical properties only change slightly. ● Silicone sealing strip color variety, according to specifications, color and packaging can be arbitrarily according to customer requirements for processing and production

Use: ● Silicone material has good sealing performance, high temperature resistance, weather resistance, aging resistance, shockproof and waterproof, and can fit all kinds of smooth surface materials ● Can back the tape self-adhesive, better sealing, high temperature resistant adhesive long-term use does not fall off. Environmental protection and safety, good insulation, high temperature resistance, small compression deformation, strong resilience, non-toxic ● Foamed silicone rubber foam evenly, density can be 0.25-0.85g/cm3, Shore hardness 8-30A. Environmentally friendly, non-toxic and odorless, good resilience, good flexibility, no bubbles on the surface, no pores. High strength, long service life, product insulation environmental protection, high and low temperature resistance, compression resistance, acid and alkali resistance, anti-aging, anti-ultraviolet. ● 100% high-quality silicone raw materials, and after strict testing, in line with environmental standards. ● Heat resistance: Silicone rubber has much better heat resistance than ordinary rubber, and can be used almost forever at 150 degrees without performance change; it can be used continuously for 10 hours at 200 degrees; it can also be used for a period of time at 350 degrees. Weather resistance: ordinary rubber is rapidly degraded under the action of ozone generated by corona discharge, while silicone rubber is not affected by ozone. And for a long time under ultraviolet and other climatic conditions, its physical properties only change slightly. ● Silicone sealing strip color variety, according to specifications, color and packaging can be arbitrarily according to customer requirements for processing and production

Use: ● Silicone material has good sealing performance, high temperature resistance, weather resistance, aging resistance, shockproof and waterproof, and can fit all kinds of smooth surface materials ● Can back the tape self-adhesive, better sealing, high temperature resistant adhesive long-term use does not fall off. Environmental protection and safety, good insulation, high temperature resistance, small compression deformation, strong resilience, non-toxic ● Foamed silicone rubber foam evenly, density can be 0.25-0.85g/cm3, Shore hardness 8-30A. Environmentally friendly, non-toxic and odorless, good resilience, good flexibility, no bubbles on the surface, no pores. High strength, long service life, product insulation environmental protection, high and low temperature resistance, compression resistance, acid and alkali resistance, anti-aging, anti-ultraviolet. ● 100% high-quality silicone raw materials, and after strict testing, in line with environmental standards. ● Heat resistance: Silicone rubber has much better heat resistance than ordinary rubber, and can be used almost forever at 150 degrees without performance change; it can be used continuously for 10 hours at 200 degrees; it can also be used for a period of time at 350 degrees. Weather resistance: ordinary rubber is rapidly degraded under the action of ozone generated by corona discharge, while silicone rubber is not affected by ozone. And for a long time under ultraviolet and other climatic conditions, its physical properties only change slightly. ● Silicone sealing strip color variety, according to specifications, color and packaging can be arbitrarily according to customer requirements for processing and production

Use: ● Silicone material has good sealing performance, high temperature resistance, weather resistance, aging resistance, shockproof and waterproof, and can fit all kinds of smooth surface materials ● Can back the tape self-adhesive, better sealing, high temperature resistant adhesive long-term use does not fall off. Environmental protection and safety, good insulation, high temperature resistance, small compression deformation, strong resilience, non-toxic ● Foamed silicone rubber foam evenly, density can be 0.25-0.85g/cm3, Shore hardness 8-30A. Environmentally friendly, non-toxic and odorless, good resilience, good flexibility, no bubbles on the surface, no pores. High strength, long service life, product insulation environmental protection, high and low temperature resistance, compression resistance, acid and alkali resistance, anti-aging, anti-ultraviolet. ● 100% high-quality silicone raw materials, and after strict testing, in line with environmental standards. ● Heat resistance: Silicone rubber has much better heat resistance than ordinary rubber, and can be used almost forever at 150 degrees without performance change; it can be used continuously for 10 hours at 200 degrees; it can also be used for a period of time at 350 degrees. Weather resistance: ordinary rubber is rapidly degraded under the action of ozone generated by corona discharge, while silicone rubber is not affected by ozone. And for a long time under ultraviolet and other climatic conditions, its physical properties only change slightly. ● Silicone sealing strip color variety, according to specifications, color and packaging can be arbitrarily according to customer requirements for processing and production

Use: ● Silicone material has good sealing performance, high temperature resistance, weather resistance, aging resistance, shockproof and waterproof, and can fit all kinds of smooth surface materials ● Can back the tape self-adhesive, better sealing, high temperature resistant adhesive long-term use does not fall off. Environmental protection and safety, good insulation, high temperature resistance, small compression deformation, strong resilience, non-toxic ● Foamed silicone rubber foam evenly, density can be 0.25-0.85g/cm3, Shore hardness 8-30A. Environmentally friendly, non-toxic and odorless, good resilience, good flexibility, no bubbles on the surface, no pores. High strength, long service life, product insulation environmental protection, high and low temperature resistance, compression resistance, acid and alkali resistance, anti-aging, anti-ultraviolet. ● 100% high-quality silicone raw materials, and after strict testing, in line with environmental standards. ● Heat resistance: Silicone rubber has much better heat resistance than ordinary rubber, and can be used almost forever at 150 degrees without performance change; it can be used continuously for 10 hours at 200 degrees; it can also be used for a period of time at 350 degrees. Weather resistance: ordinary rubber is rapidly degraded under the action of ozone generated by corona discharge, while silicone rubber is not affected by ozone. And for a long time under ultraviolet and other climatic conditions, its physical properties only change slightly. ● Silicone sealing strip color variety, according to specifications, color and packaging can be arbitrarily according to customer requirements for processing and production

Use: ● Silicone material has good sealing performance, high temperature resistance, weather resistance, aging resistance, shockproof and waterproof, and can fit all kinds of smooth surface materials ● Can back the tape self-adhesive, better sealing, high temperature resistant adhesive long-term use does not fall off. Environmental protection and safety, good insulation, high temperature resistance, small compression deformation, strong resilience, non-toxic ● Foamed silicone rubber foam evenly, density can be 0.25-0.85g/cm3, Shore hardness 8-30A. Environmentally friendly, non-toxic and odorless, good resilience, good flexibility, no bubbles on the surface, no pores. High strength, long service life, product insulation environmental protection, high and low temperature resistance, compression resistance, acid and alkali resistance, anti-aging, anti-ultraviolet. ● 100% high-quality silicone raw materials, and after strict testing, in line with environmental standards. ● Heat resistance: Silicone rubber has much better heat resistance than ordinary rubber, and can be used almost forever at 150 degrees without performance change; it can be used continuously for 10 hours at 200 degrees; it can also be used for a period of time at 350 degrees. Weather resistance: ordinary rubber is rapidly degraded under the action of ozone generated by corona discharge, while silicone rubber is not affected by ozone. And for a long time under ultraviolet and other climatic conditions, its physical properties only change slightly. ● Silicone sealing strip color variety, according to specifications, color and packaging can be arbitrarily according to customer requirements for processing and production

Use: ● Silicone material has good sealing performance, high temperature resistance, weather resistance, aging resistance, shockproof and waterproof, and can fit all kinds of smooth surface materials ● Can back the tape self-adhesive, better sealing, high temperature resistant adhesive long-term use does not fall off. Environmental protection and safety, good insulation, high temperature resistance, small compression deformation, strong resilience, non-toxic ● Foamed silicone rubber foam evenly, density can be 0.25-0.85g/cm3, Shore hardness 8-30A. Environmentally friendly, non-toxic and odorless, good resilience, good flexibility, no bubbles on the surface, no pores. High strength, long service life, product insulation environmental protection, high and low temperature resistance, compression resistance, acid and alkali resistance, anti-aging, anti-ultraviolet. ● 100% high-quality silicone raw materials, and after strict testing, in line with environmental standards. ● Heat resistance: Silicone rubber has much better heat resistance than ordinary rubber, and can be used almost forever at 150 degrees without performance change; it can be used continuously for 10 hours at 200 degrees; it can also be used for a period of time at 350 degrees. Weather resistance: ordinary rubber is rapidly degraded under the action of ozone generated by corona discharge, while silicone rubber is not affected by ozone. And for a long time under ultraviolet and other climatic conditions, its physical properties only change slightly. ● Silicone sealing strip color variety, according to specifications, color and packaging can be arbitrarily according to customer requirements for processing and production