Products

Silicone foam seal - 0.4 density / 0.7 density foam

Suitable for lightweight cushioning and highly elastic sealing

- Commodity name: Silicone foam seal - 0.4 density / 0.7 density foam

- Product Description

-

Product Description

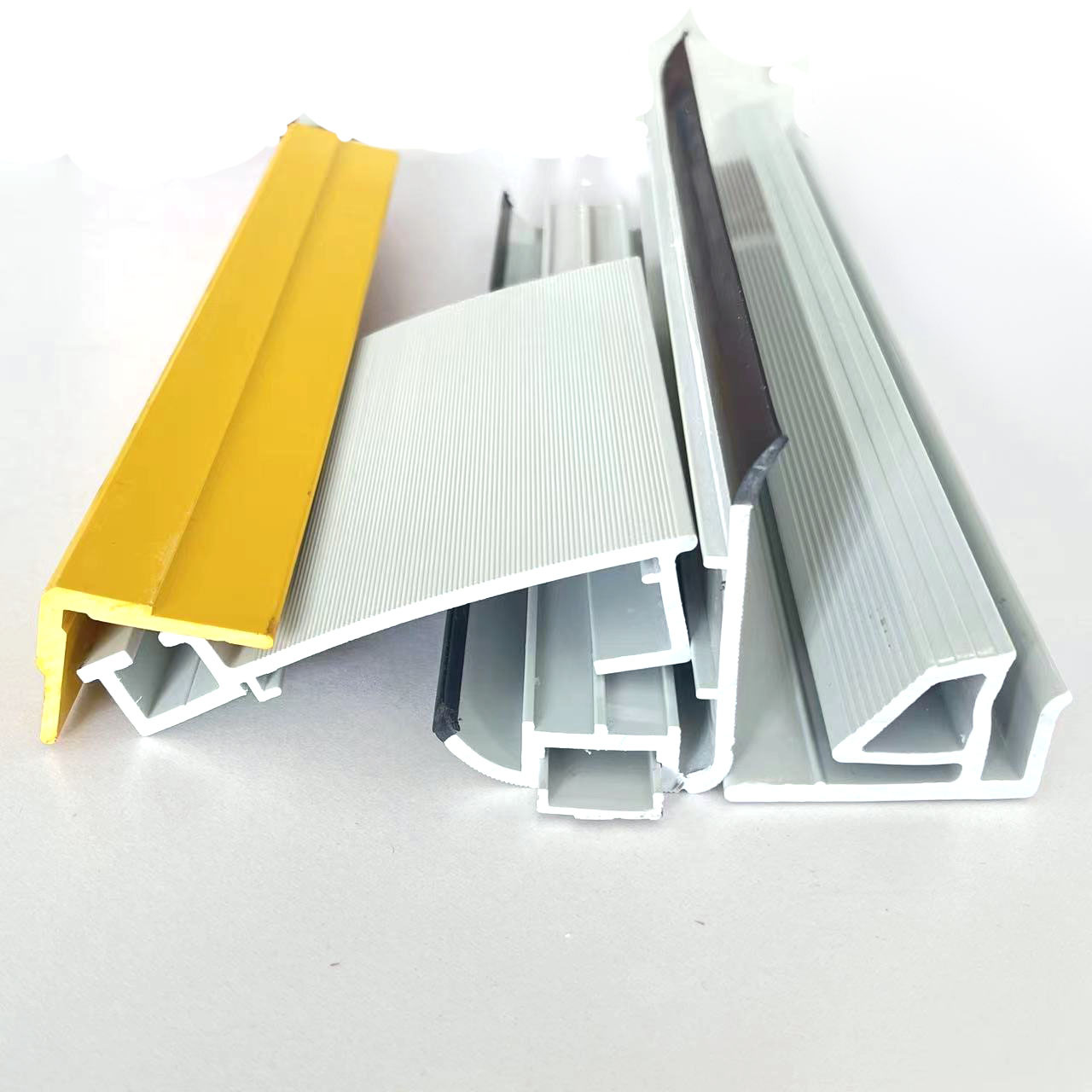

Silicone foam sealing strips are high-performance sealing products made from high-quality silicone materials using a foaming process. They have excellent temperature resistance, elasticity, and sealing performance. Two common density versions are available to meet different application needs—0.4 g/cm³ (low density) and 0.7 g/cm³ (medium density)—suitable for lightweight cushioning and high-elasticity sealing applications, respectively.These sealing strips are widely used in building doors and windows, home appliances, automotive manufacturing, and other fields. They effectively prevent dust and water while providing good sound insulation and shock absorption.

Classification

Classification Dimension Description

Material Pure silicone foam material (food grade/industrial grade optional)

Density Selection 0.4 g/cm³ (low density), 0.7 g/cm³ (medium density)

Color White, black, gray, etc. (customizable)

Shape U-shaped, D-shaped, square, round, irregular (customizable according to needs)

Function Sealing, heat insulation, shock absorption, dust prevention, waterproof, noise reduction

Application Fields: Home appliances, automobiles, medical, construction, electronic equipment

Product Specifications

Density: 0.4 g/cm³ (low density), 0.7 g/cm³ (medium density), or others

Temperature Range: -60°C to +200°C

Hardness: Shore A 25±5 (0.4 density) Shore A 40±5 (0.7 density)

Tensile Strength: ≥1.5 MPa (0.4 density) ≥3.0 MPa (0.7 density)

Elongation at Break: ≥200% (0.4 density) ≥150% (0.7 density)

Dimensions: Standard width: 10mm ~ 80mm, standard thickness: 3mm ~ 20mm, length: customized as needed

Features and Advantages

High and Low Temperature Resistance: Maintains stable performance under extreme temperatures.

Soft and Highly Elastic: Good compression rebound, suitable for dynamic sealing environments.

Environmentally Friendly and Non-toxic: Food-grade silicone material, safe and reliable.

Waterproof and Dustproof: Closed-cell structure design effectively prevents water vapor and dust from entering.

Easy to Install: Can be cut, pasted, or embedded for easy installation.

Density Difference Comparison

Characteristics: Density 0.4 (low density) / Density 0.7 (medium density)

Feel: Softer, lighter / Slightly harder, supportive

Compression Deformation: Easily compressed, suitable for light pressure sealing / Strong compressive strength, suitable for long-term sealing

Rebound Elasticity: Higher / High

Applicable Scenarios: Appliance door seals, lightweight equipment, temporary sealing / Car doors and windows, industrial equipment

Usage Scenarios

Application Field Typical Use Examples

Home Appliance Industry Refrigerator, microwave oven, oven, washing machine door seals

Automotive Industry Car doors, trunk, sunroof, engine compartment seals

Building Doors and Windows Fire doors, soundproof windows, aluminum alloy door and window seals

Electronic Products Waterproof phone cases, outdoor enclosures, control cabinet seals

Packaging Method

Standard Packaging: 50 meters per roll, wrapped in PE film and then packed in a carton for moisture and pressure resistance.

Custom Packaging: Supports segmented cutting, vacuum packaging, pallet packaging, etc., to meet the needs of large-scale export transportation.

Ordering Instructions

Minimum Order Quantity (MOQ): 100 meters (specific quantity can be adjusted according to customization needs)

Delivery Time: Standard products 5-7 days; customized products 10-15 days

Payment Method: T/T bank transfer (30% prepayment, balance before shipment)

Sample Service: Free samples are available (limited to standard specifications), and sample fees can be deducted from bulk orders

Keywords:

Product Consulting

Related Products